SET SCAN OP1000 Procurement Technical Requirements

SETSCAN is a high frequencystatistical Extinction Tomography patternator developed to characterize sprays on-line.

SETSCAN Six-axis patternator

Model:SETSCAN OP-1000-6

Features

- Characterization of sprays for cone angle,asymmetry, presence of streaks and voids, and patternation number.

- Graphical user interface with point and click operation including one click calibration .

- Real time display of cone angle and asymmetry ratio .

- Planar surface area densities that are fully correlated with the local evaporation and combustion rate.

- Patternation number for standard eight pie configuration (with rotation facility to change reference angle) .

- Linear patternation number .

- Insensitivity to alignment of nozzle center.

Technical Parameter requirements

Radial Resolution: Up to 1.5 mm

Angular resolution: Up to 7 degrees

Power input: 220VAC, 50 Hz

Number of pixels: 512 per axes

Max. diameter of spray: 10 inches

Array scan rate: 1KHz/9 KHz

Weight: 160 lbs

GUI update rate: 30 Hz

Dimension: 50” diameter, 10” tall

Functional requirements

Measure the circumferential and angular distribution of spray

Measure the spray cone angle

Support the R&D of water nozzle

Inspection (production) of batch products

Module configuration requirements

SETSCAN needs its own data acquisition and data analysis system (including software and hardware like PC).

Be able to communicate with the customer’s test system, including the transmission of SETSCAN test data, and the control of starting or ending the SETSCAN test.

Related communication protocol of SETSCAN equipment is required.

Calibration and calibration tools are required.

Characteristic

Stainless steel top cover impervious to most liquids .

Covered optical and electronic components.

Rugged cast aluminum enclosure for shop floor applications .

Automatic nozzle centering chuck .

Mounting provision for customer platforms or self standing .

Minimal technical expertise required for operation .

Out-of-box deployment capability with quick set up and calibration .

100 µs patternation of transient trigger and injector sprays.

Accessories and options

Control panel interface (optional)

SETscan patternation software

Quality audit module

DAQ system

Fully integrated spray stand

Installation and set-up

Five year service contract

Spare lasers and lenses

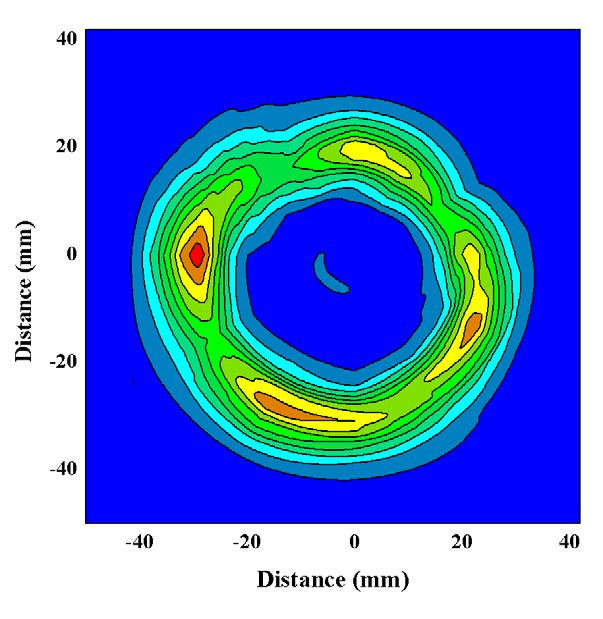

Contour plot of drop surface area

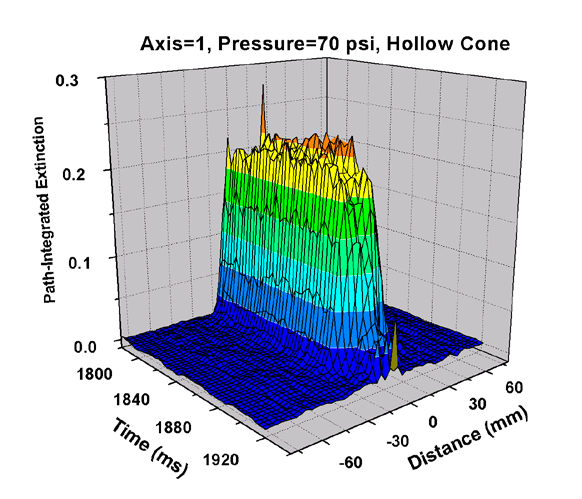

Transient spray patternation

0 Comments