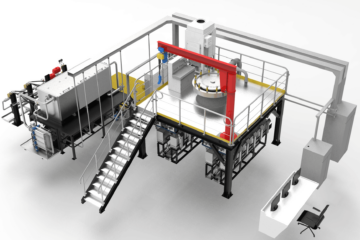

Nozzle Test Bench (Type:JM-F-03)

Profile

The nozzle test bench is mainly used to test the performance of multi-type fuel nozzles under different oil pressures, such as flow rate, angle, distribution, and unevenness.

Feature

The operator control panel is positioned on an angle at the front of the tester to provide ergonomic operation. The spray chamber, pressure, temperature, and flow readouts are positioned to allow continuous observations of the test process.

A polycarbonate plastic test chamber is conveniently located on the tester for mounting the fuel nozzles and is provided with a mechanical protractor to evaluate the nozzle spray pattern. A light, which is switched on with the supply pump, is located under the clear base of the spray chamber. Lighting the nozzle spray from underneath is the best way to illuminate the spray cone, aiding the observation of spray quality.

Advancement and maturity in techniques, high efficiency and reliability of operation, modular design convenient for maintenance, upgrading and potential expandability, highly open instrumentation and environmental protection are essential characteristics of the test equipment.

Technical Parameter (Customized according to the CMM)

| Item | Technical Parameter | |

| Flow & Pressure Test | Primary Supply Flow Indicator | 0.8~1000kg/h(1.76~2205pph) |

| Secondary Supply Flow Indicator | 0.8~100kg/h(1.76~220.5pph) | |

| Supply Pressure | 0.05~8MPa (adjustable) | |

| Supply Temperature | 15~40 ℃,Control accuracy±1.5℃ | |

| Accuracy | Fuel supply flow rate | ±0.25%RS |

| Fuel supply pressure | ±0.25%FS | |

| Temperature | ±1℃ | |

| Leak-Test | 0~8MPa(adjustable) | |

| Spray cone angle measurement accuracy | Mechanical probe method | |

| Fuel Spray Patternation Test | Visual method, mechanical collection method | |

0 Comments